Featured products achieve semi-standardization of inventory

pcd inserts with chip breaker /aluminum-based silicon carbide milling cutters /PCD cutter for chain saw blade cutting machine

Featured product 1: PCD cutting inserts with chip breaker

The 010 grit size PCD inserts (showing above picture)double the cutting speed simultaneously, improves the chip state, improves the processing quality by increasing the chip breaking groove, and escorts the parts identification and automatic grabbing in the automated and intelligent production line.

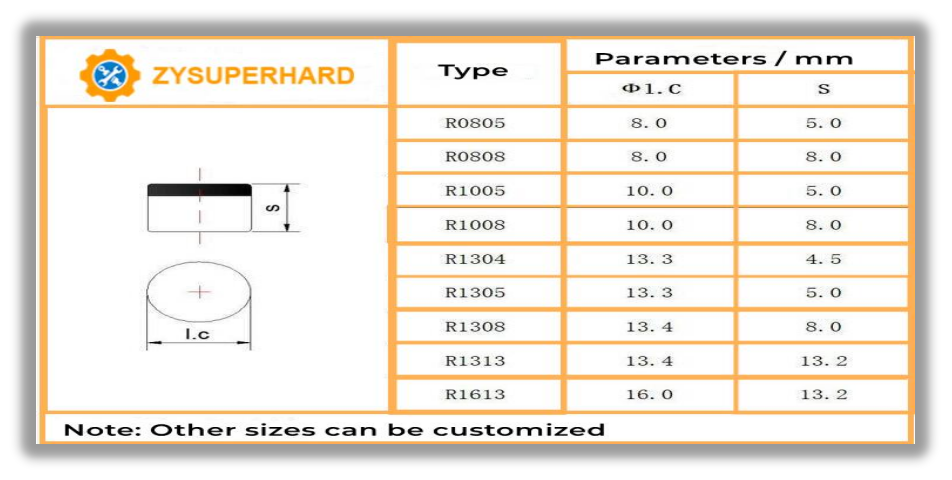

PCD chip-breaking groove type and parameters of pcd inserts with chip breaker

Chip condition with chip-breaker or not for pcd inserts

Featured products 2: aluminum based silicon carbide and other MMC milling tools-PCD milling cutters

As a modern new composite material widely used in aerospace, military, and other fields, the density is 1/3 of steel. Still, the strength is higher than pure aluminum and medium carbon steel, with high wear resistance. Still, at the same time, the processing difficulty is also very large, such as fast tool wear, high production costs, and low processing efficiency. Technical team, after repeated testing and practice, the current 010 material PCD tool in aluminum-based silicon carbide milling and drilling process has made stable development, and with the PCD milling cutter, we achieve semi-finished products stock, greatly shortening the delivery cycle. The following is the application case of the ZY PCD milling cutter in satellite parts (because the machined part is a secret part, it is not shown here)

Processing method: milling processing

Cutter used: D4 PCD end mill

Machine tool: Beijing Jing Machine

Processing part: step cleaning root

Application industry: Satellite parts

Use effect: the service life of a single cutting edge is 4 hours, which is 12 times the life of cemented carbide milling cutter, and 1.5 times the life of a domestic brand PCD milling cutter.

Featured Product 3:PCD cutter for chain saw blade cutting machine

PDC cutter (polycrystalline diamond compact) is widely known for drilling tools used to directly break the rock at the bottom of the hole in engineering drilling, and another field is the PDC chain saw blade for marble mining.

Marble belongs to non-renewable resources; in mining, to better preserve the integrity of marble and improve the rate of waste, more enterprises choose chain saws instead of rope saws to cut marble. The pdc cutter equipped with the chain saw machine is the PDC composite blade, and a device needs to be matched with dozens to more than one hundred pieces.

The ZY superhard PCD cutter for chain saw blade cutting machine has excellent comprehensive properties such as high strength, wear resistance, impact toughness, and thermal stability. It doesn't break abnormally and has been semi-standardized.

![]()

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat