usually 0°, 10°

generally 7°, 11°, 20°

0.05mm, 0.1mm, 0.2mm, 0.4mm, 0.8mm, 1.2mm

adjust according to specific processing needs

Adjust according to specific processing requirements

Adjust according to specific processing requirements

Affects the cutting force and the formation of chips, the larger the front Angle, the Smaller the cutting force, but too large front Angle may lead to faster tool wear.

Affects the contact area between the tool and the workpiece, the larger the back Angle, the less friction, but too large back Angle may lead to reduced tool strength.

Affects the stress distribution in the cutting process, smaller arc radius can Reduce the cutting force, but may lead to faster tool wear.

Affects the cutting force and cutting heat, the larger back cutting amount will lead to higher cutting force and cutting heat.

Affects the cutting force and surface roughness, a larger feed will lead to higher cutting force, but can reduce the surface roughness.

Affects cutting heat and tool wear, higher cutting speed can reduce cutting force, but may lead to higher cutting heat and faster tool wear.

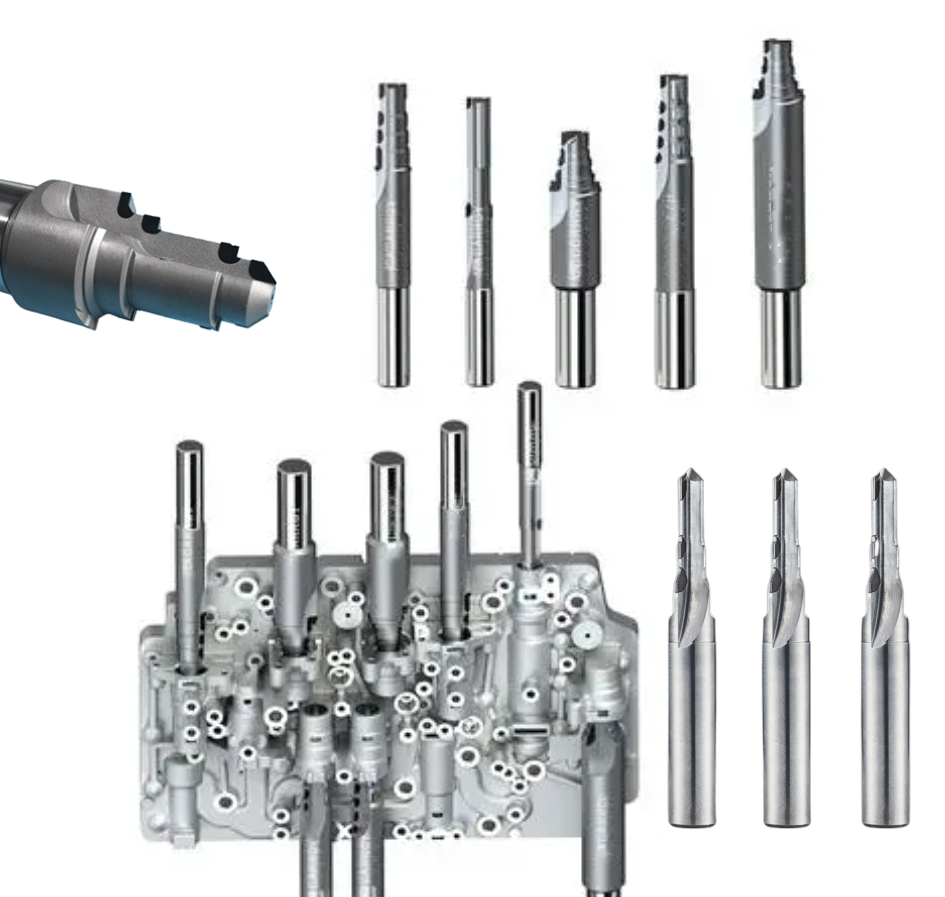

PCD tool has extremely high hardness, good wear resistance, suitable for Long-term processing.

PCD tool has high thermal conductivity, which can quickly transfer cutting heat and reduce tool thermal deformation.

The low friction coefficient of PCD tool can reduce the cutting force and improve the processing efficiency.

PCD tool thermal deformation is small, suitable for high precision machining.

PCD long tool life, reduce the number of tool replacement, improve production efficiency.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat