Have you ever wondered what's the difference between PCD and carbide reamers? If you're in the metalworking industry, this question is not new. Let's dig deeper into these essential tools and see which outshines the other.

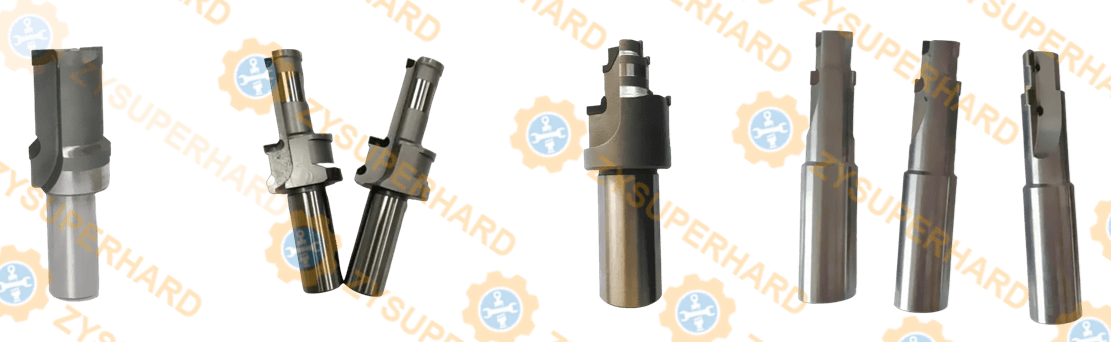

PCD stands for Polycrystalline Diamond. PCD reamers, made up of tiny diamond particles, are incredibly hard, durable, and resistant to wear. These tools are designed to deliver precision in machining tasks.

So, what's the deal with PCD reamers? Their extreme hardness enables them to maintain sharp cutting edges for extended periods. This quality translates into fewer tool changes, increased productivity, and lower operational costs. Moreover, they resist high temperatures, providing stability under high-speed operations.

On the other hand, we have carbide reamers. These reamers are made of carbide, a hard and durable material. Carbide tools, including reamers, are popular for their versatility and broad application range.

Why should you opt for carbide reamers? Their hard nature enables them to efficiently cut through various materials, including steel, cast iron, and even toughened plastics. In addition to this, carbide reamers are less expensive than their PCD counterparts.

Now that we've set the stage let's compare these reamers head-on.

PCD reamers, with their diamond particles, top the hardness scale, outlasting carbide reamers. However, carbide reamers hold their own with good durability.

Thanks to their heat resistance, PCD reamers can operate at high speeds without losing precision. Carbide reamers, while not as fast, provide reliable and efficient cutting across various materials.

Regarding heat resistance, PCD reamers have the upper hand due to the inherent qualities of the diamond.

Carbide reamers are generally less expensive and provide a versatile tooling solution for various applications.

Both reamers find extensive applications in the aerospace, automotive, electronics, and metalworking industries.

Consider the material to be machined, required precision, speed, heat resistance, and budget when choosing between PCD and carbide reamers.

Each tool has its strengths in the contest of PCD VS carbide reamers. PCD reamers are superior in hardness, durability, and speed, while carbide reamers offer versatility and cost-effectiveness. Therefore, the "superior" tool depends on the specific requirements of your project.

What materials are suitable for PCD reamers? PCD reamers are ideal for non-ferrous metals and abrasive materials such as aluminum, copper,ceramics, and composites.

Can I use carbide reamers on steel? Carbide reamers can machine various materials, including steel and cast iron.

Are PCD reamers worth the high cost? The investment can be worth it if you require high precision and speed and work with materials suitable for PCD.

What factors should I consider when choosing a reamer? Consider the material you are working with, the required precision, operating speed, heat resistance, and budget.

What are the main differences between PCD and carbide reamers? PCD reamers are generally harder, more durable, and can operate faster. Carbide reamers, however, are versatile, efficient across many materials, and generally more cost-effective.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat