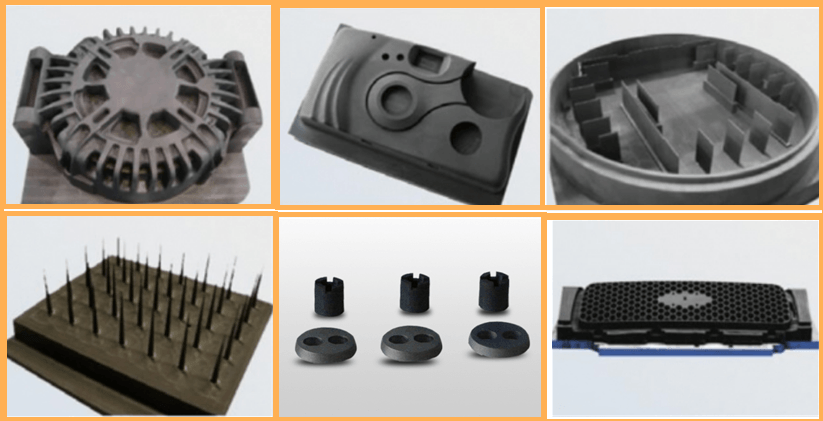

Graphite is a material that is very easy to cut.With the development of high and new technology, the manufacturing process of graphite materials continues to improve; the market of graphite high-speed milling machines came into being, and it can meet the needs of different processing graphite materials emerge in endlessly. Because of its high-temperature strength, low thermal expansion coefficient, good machinability, and good thermal and electrical conductivity, many factories currently produce graphite electrodes, graphite molds, graphite crucibles, 3D hot bending molds (mainly mobile phone glass hot bending molds) and other graphite products. In Europe, where manufacturing technology is leading, more than 90% of electrode materials in mold enterprises have used graphite.

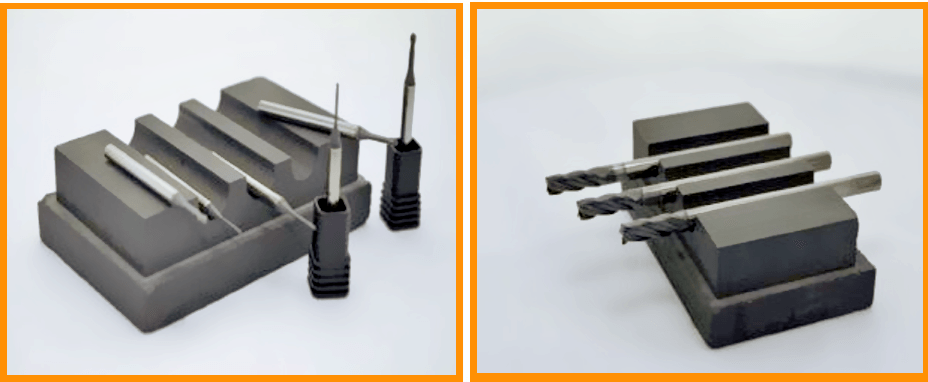

Due to the high abrasive property of graphite material, brittleness, the intermittent effect of graphite chip formation in the process of graphite processing, the tool surface under the action of alternating cutting stress and cutting impact, easy to occur early damage, rapid wear, and other phenomena, so the processing of graphite tool requirements has higher wear resistance and impact resistance. ZY Superhard supplies PCD graphite turning tools, PCD milling tools, PCD chamfering tools, and PCD diamond-coated tools in processing graphite, and most graphite enterprises recognize them. They not only effectively solve the problem of rapid tool wear, but also significantly improve production efficiency.

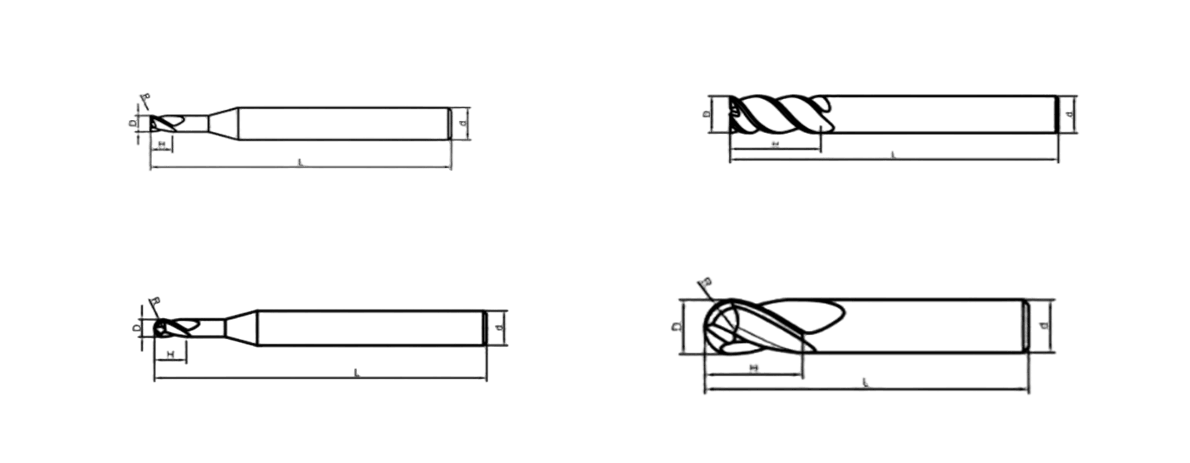

Under normal circumstances, high-speed processing graphite will use turning tools, hole processing tools, etc. When choosing the milling processing graphite tool, we should consider the cutting way, vacuum, impregnated EDM fluid processing, and cutting speed. When milling the graphite clockwise, the cutting vibration is less than that of the reverse milling method.; during milling graphite, it is necessary to clean up the graphite dust on the workpiece surface in time, which is conducive to reducing the tool's secondary wear and the influence of graphite dust on the machine tool lead screw and guide rail. In the final milling process, selecting the appropriate high speed and the corresponding large feed will improve production efficiency.

After many experiments and applications, the diamond (pcd) graphite milling cutter is both wear resistance and cost reduction. It is an ideal tool material for high-speed milling of graphite.

The advantages of diamond pcd graphite milling cutter in high-speed milling of graphite electrodes:

(1) High hardness and wear resistance

In high-speed milling processing graphite, the hardness of the tool material is necessary to be much higher than the hardness of graphite material. the hardness of the tool material is high, its wear resistance is better, and diamond is the most superhard material found at present, such as PCD025 and PCD302, which is the best grit in diamond tool wear resistance.

(2) High strength and endurance

Diamond tool material has high strength and resistance and can accept large cutting force, vibration, and impact; polycrystalline diamond PCD tools and CVD diamond coating tools, are the use of carbide tool as the substrate in the cutting site welding or coating diamond material, combined with the high hardness of diamond and carbide high toughness, to avoid brittle fracture of the tool.

(3) Long life and low cost

Diamond pcd tool hardness is not easy to wear, has a long life, has high processing efficiency, and can reduce costs.

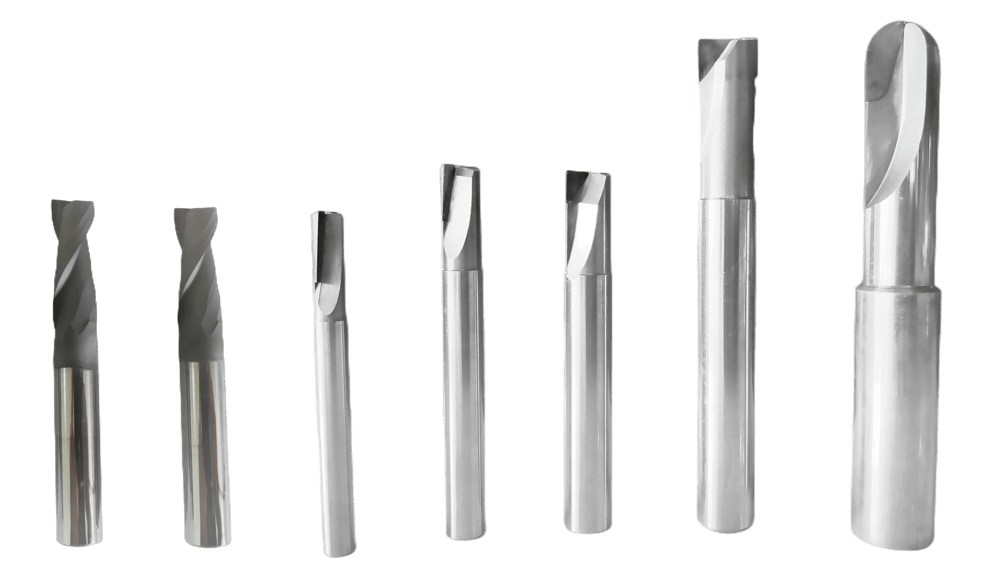

ZY provides a PCD milling cutter, PCD reamer, PCD drilling bit, PCD non-standard tool customization and other products, PCD tool production and non-standard tool application guidance, and other services; welcome to customize.

Extension: PCD tool and CVD diamond-coated tool

Polycrystalline diamond PCD tool and CVD diamond coated tool are ideal for graphite material processing. CVD diamond-coated device has the advantages of high hardness, good wear resistance, etc. However, the cost of the diamond-coated tool is always high, and with the increasingly mature production technology of the PCD tool, the cost and price are also down. Therefore, the application of PCD tools in the field of processing graphite materials is more and more extensive.

It generally chooses CVD diamond-coated graphite tools for micro-diameter and small-hole machinings, such as graphite drills and milling cutters with small and micro-diameters less than 3mm, it is better to use CVD diamond-coated graphite tools. Suppose more than 3mm,polycrystalline diamond pcd tool has more cost-effective. In that case, Many factories manufacture a variety of PCD tools, such as PCD turning tools, pcd drills, pcd end milling cutters, pcd ball end milling cutters, pcd slot cutters, pcd boring cutters, etc.

Contact: Nina Qiao

Phone: 86-13526572721

E-mail: cutting@zy-superhardtools.com

Whatsapp:86-13526572721

Add: AUX Industry,Zhengzhou City,Henan Province,China

We chat